![]() Thermoforming Solutions for Your Company

Thermoforming Solutions for Your Company

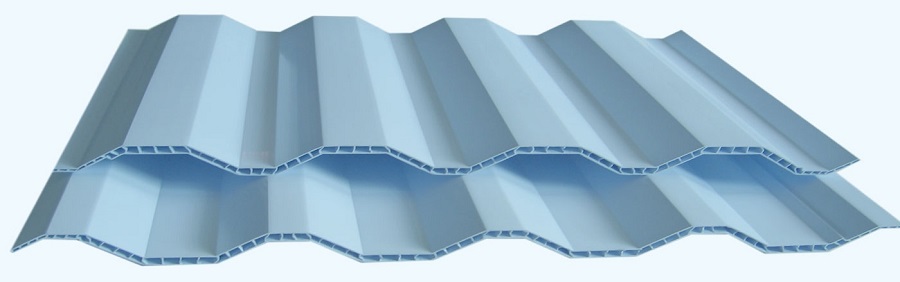

Twin sheet thermoforming is the process of heating adjacent plastic sheets simultaneously then forming and fusing the two sheets together in order to create the finished product. The coming together of two sides during twin-sheet forming makes it ideal for constructing double-walled and hollow industrial products. Vending-machines, bed liners, air ducts, and pallets some of the custom plastics constructed using this process.

Twin-sheet forming is a complex system with many conditions that need to be met in order to thermoform a viable product. When forming two sheets instead of one, just as the twin thermoforming process suggests, the thermal bonding between the two sheets must be precise and properly aligned. A complete understanding and control of the conditions in play while twin-sheet thermoforming is required, as well as the appropriate vacuum and cooling devices.

![]() Twin-Sheet Thermoforming

Twin-Sheet Thermoforming

The two sheets in twin forming must be in complete sync with one another. This is to make sure the plastic can be matched with their pressed points. The pressed points are the areas where the two molds will be pressed together. There is no allowance for error during the fusion of both sheets. They must be perfectly aligned in order to join together properly.

The Twin-sheet process allows for hot air to be trapped within. This can cause the panel to collapse. To combat this, holes are positioned along the face of the panel that acts as a ventilation system. Cool air is brought in and the holes are placed in a way that conceals their presence.

Whether painted or unpainted, surface finish is important when thermoforming. Shadowing, a term used that represents noticeable inconsistencies in surface finish, can happen on sides near where the twin-sheets were pressed together. To eliminate shadowing, the mold can be bead-blasted which will give the panel a textured finished.

When considering thickness, it is best that the difference in depth between the bottom and top sheets be 0.0625 of an inch or less. A variance greater than that would risk the twin-sheets being out of sync. The thicker sheet would take longer to heat and cool, causing the thinner sheet to potentially distort.

![]() Advantages of Twin-Sheet Thermoforming

Advantages of Twin-Sheet Thermoforming

a. Twin-sheet forming allows for a two-color product option and custom color layering

b. Due to its unique process, hollow products can be formed with a separate component inside

c. Twin forming has the ability to include internal reinforcements such as rigid foam components

d. Twin-sheet thermoforming has increased structural stability

e. This thermoforming process can have molded in attachments

f. Has a size capability of 8″ x 8″ to 7′ x 11′

g. Allows for air and wiring ducts

h. Can accommodate multiple textures and have variable wall sizes

Twin sheet thermoforming can be used to create heavy-duty industrial parts along with formed features. The parts created are high in strength, rigidity, and stiffness. Twin sheet thermoforming incorporates hollow cavities in the parts that contribute to their lightweight but heavy-duty properties. This plastic forming process is most commonly used in products that require maximum durability, a secure structure, and as little weight as possible.

![]() Twin Sheet Thermoforming Materials

Twin Sheet Thermoforming Materials

a. TPO – Thermoplastic Polyolefins have high impact resistance and can keep up performance in cold and high heat applications

b. ABS – Acrylonitrile Butadiene Styrene can be used across a number of products due to its impact and chemical resistant properties

c. HDPE – High-Density Polyethylene Sheets have a high impact strength and are used for industrial products

d. HIPS – High Impact Polystyrene is lightweight, inexpensive, and is commonly used in food packaging and housing applications

e. Acrylic – Acrylic carries great shatter resistance, weather resistance, resilience, and pliancy